GLASS UNLIMITED

Technology :

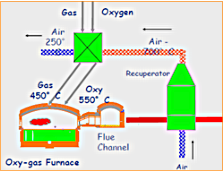

One example is hot oxy-combustion.

The HOxyGas project aims to demonstrate a new type of production system for automotive flat glass that has a lower carbon footprint than comparable systems in terms of reduced fossil fuel consumption and reduced GHG emissions. An innovative process is proposed to produce glass that uses only hot natural gas (450°C) and hot oxygen (550°C) .

The main environmental results expected of the project are (vs. air-gas combustion)

CO2 emissions will be reduced by 5.5%

NOX: specific emissions will be reduced by 79.2%

SOX: specific emissions will be reduced by 34.5%

Dust (particles) will be reduced by 67.7%

Energy consumption will be reduced by 19.7%

The HOxyGas project aims to demonstrate a new type of production system for automotive flat glass that has a lower carbon footprint than comparable systems in terms of reduced fossil fuel consumption and reduced GHG emissions. An innovative process is proposed to produce glass that uses only hot natural gas (450°C) and hot oxygen (550°C) .

The main environmental results expected of the project are (vs. air-gas combustion)

CO2 emissions will be reduced by 5.5%

NOX: specific emissions will be reduced by 79.2%

SOX: specific emissions will be reduced by 34.5%

Dust (particles) will be reduced by 67.7%

Energy consumption will be reduced by 19.7%

The glass production process is very energy intensive. Therefore, over the last years many different techniques have been developed to reduce energy consumption and GHG emissions.

Duration of the project : 1st June 2012 to 31 January 2017

Total budget : 12.102.320 €

EU contribution : 4.250.924 €

HOxyGas by AGC Glass Europe